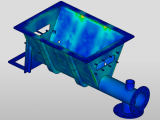

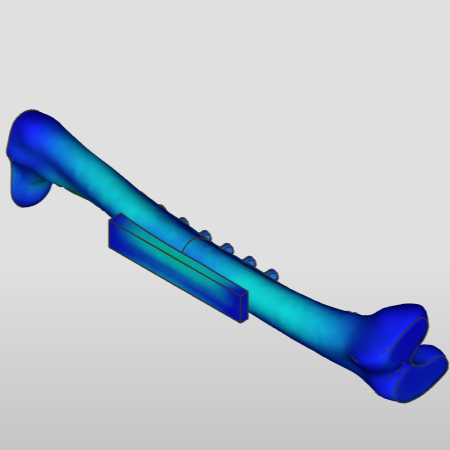

Simright Design Feeder Box

MechanicsDuring the working process, the vibrating feeder box is subject to fatigue damage due to the alternating load under the natural frequency. Therefore, attention should be paid to avoid stress concentration in the initial structural design, and the work efficiency can be improved while ensuring the reliability of the feeder. .